Hydrostatic Compressed Air Tank Testing

KG Power Systems is an authorized Hydrostatic Tank Testing Facility for the FDNY. Our Service Technicians have been trained and certified by the FDNY (Certificate of Fitness Holder). We perform onsite Hydrostatic Tank Testing in the New York Metro Area.

The tank testing is done through K&G Power Systems' Service Department. K&G will set up an appointment to have your tank tested. A Certificate of Fitness holder will perform an on-site Hydrostatic Tank Test and will issue you a signed affidavit that your tank has passed the test. K&G will also mail the certification to the fire department.

The tank testing is done through K&G Power Systems' Service Department. K&G will set up an appointment to have your tank tested. A Certificate of Fitness holder will perform an on-site Hydrostatic Tank Test and will issue you a signed affidavit that your tank has passed the test. K&G will also mail the certification to the fire department.

Why Does the FDNY Require Tank Testing?

Air compressor tanks contain pressurized air that is used to operate tools and machinery for residential, commercial, and industrial applications. Moisture, compressor lubricants, and contaminants from condensate collects in air tanks causing corrosion which leads to leaks in fittings and seams.

The purpose of periodic hydrostatic testing of compressed air tanks is to validate the tank’s integrity and safety. Inspections and hydrostatic testing of compressed air tanks have shown that there are a considerable number of cracked and damaged vessels. Damaged air tanks can result in leaks or rupture failures.

Potential health and safety hazards of leaking air tanks include rupture failures that can be catastrophic and cause considerable damage to life and property. Periodic inspection and hydrostatic tank testing of compressed air tanks in accordance with the appropriate OSHA, FDNY, and DOT codes and regulations is essential to worker safety and health.

FDNY Requirements For Hydrostatic Tank Testing:

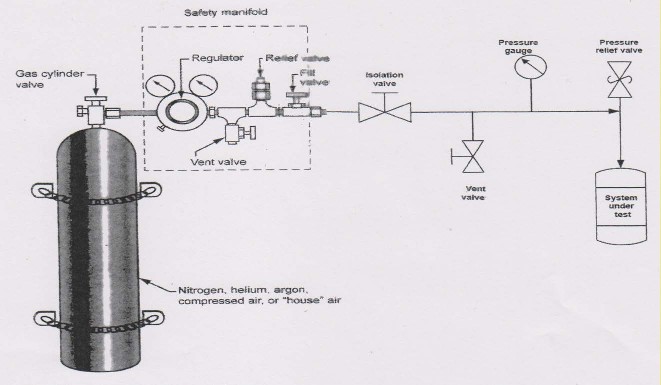

1. Hydrostatic tank testing must be completed by a licensed certified tank tester with special equipment designed for the task.

2. The tank should be tested every five years.

3. The tank must be tested more often than every five years if there are any visual signs of degradation or damage.

4. Requirements under the law state that the tank to be tested must be filled with water and pressurized to 167% of the maximum operating pressure listed on the side of the tank.

5. The tank, including all of the valves and other closures, must hold the pressure test for at least 30 minutes without leaking or bulging.

6. Details and requirements for hydrostatic testing are covered under OSHA regulations section 180.407.